Every individual in the Printgraphics team channels love and respect into projects, so when you print with Printgraphics you’re in caring hands.

What we do

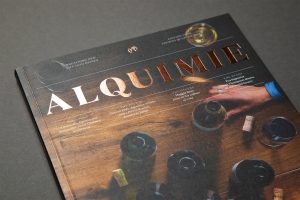

Printgraphics Printgreen is your most trusted Print partner for publications, catalogues, brochures and anything print related. Here are some samples of our work..

Why we do it

Print is an unmatchable experience, a physical product with impact to engage the heart and mind. We love providing clients expert print solutions and service with an environmentally inspired conscience.

It all starts with hello!

It all begins with a simple hello. It’s the most basic conversation starter to endless printing opportunities. Simply reach out to one of our team members via mobile, email or social media.